Discover all the news and articles from TNUMIS Magazine exclusively

Coin Striking: A Skilled Technique

Far more than just the production of metal coins, minting is a meticulous process that combines technical know-how, history and culture. As numismatists, we are the guardians of this fascinating heritage. Let’s delve into the complex world of minting, to highlight the details and techniques that make each coin a work of art in its own right.

The birth of coinage

The history of coinage goes back to antiquity. The first coins were produced in the 7th century BC, in Asia Minor, more precisely in Lydia, a region of present-day Turkey. We’re talking here about the first minted and signed coins in the Western world. Made from electrum, a natural alloy of gold and silver, these coins were marked with a seal guaranteeing their authenticity. This revolutionary concept quickly conquered the Mediterranean world, and evolved over the centuries into the sophisticated art we know today.

Coins alloys

The choice of metals and their composition is a key element in coinage: gold, silver, bronze, copper… Each metal brings its own unique properties, from the nobility of gold to the durability of bronze. Experienced numismatists understand the importance of these choices and appreciate the subtle combination of metals that gives each coin its distinctive character.

The evolution of tools and techniques

Minting is a demanding craft requiring the mastery of specific tools. It consists of striking a blank, using a press, between two corners. However, minting techniques have evolved over time.

Hammer striking

This was the main technique from ancient times until the introduction of mechanical processes. After extraction, the metal (gold, silver, copper or bronze) was melted and poured into a mold to produce blanks. These objects, in the shape of small disks of varying roundness and thickness, were then placed between two negatively engraved corners: the obverse and reverse.

Engraving the corners was a crucial step in the process of creating a coin. This is where the engraver, often overlooked by the general public, came into play. Armed with chisels and punches, the engraver breathed life into the coin by creating motifs, portraits and symbols that told a story. Every detail, every contour, was meticulously studied to create a miniature work of art that today transcends mere monetary value.

Once the corners had been engraved, the obverse was fixed to an anvil, while the reverse was held in place with clamps. The coiner would then strike the anvil with force and precision, allowing the design to sculpt the blank on each side. This resulted in pieces with irregular contours, as the sides were then cut out with a chisel.

The hammer, used to strike the piece, had to be handled with a skill that combined strength and delicacy. The anvil, on which the piece is placed before striking, had to be perfectly levelled to ensure a clean, uniform impression. Every stroke of the hammer had to be calculated, every movement considered, to create a piece that was both aesthetically pleasing and up to quality standards.

Pendulum coinage

Pendulum coinage was tried out under Henri II, but really took off under Louis XIII with the creation of the Louis d’or. In 1640, sculptor and engraver Jean Varin designed the famous gold coin to be minted using this new technique.

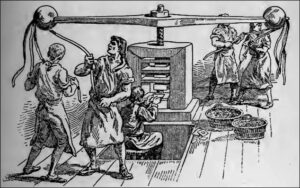

Pendulum coinage, also known as mill striking, offers a new mastery of high technical and artistic quality. This press was operated manually by an arm weighted with two weights at either end. Mechanical force replaced the hammer and anvil, and the result was a more regular execution than with hammer striking.

The efficiency of this technique meant that thirty coins could be minted per minute, compared with a dozen with the hammer.

Lever striking

Lever striking was invented in England in the 18th century, using the modern steam-powered lever press process. Its output was 50 pieces per minute.

Since the twentieth century, lever presses have been powered by electricity and are much more powerful. Modern presses, like the one installed in Pessac, are now computerized and automated. Although minting remains a traditional craft, modern technology has considerably improved the process. On average, 800 coins are produced per minute. High- precision presses, computer-assisted engraving techniques and advanced quality control methods have pushed back the limits of perfection. As a result, numismatists can admire coins of unrivalled quality, combining the elegance of the past with the precision of the present.

Minting is much more than a simple production technique. It’s a marriage of tradition and innovation, of craftsmanship and cutting-edge technology. Each coin is the fruit of a meticulous process, where every stroke of the hammer, every engraved detail, contributes to creating a work of art in its own right. Numismatists, as guardians of this heritage, play an essential role in the preservation and appreciation of this ancient and fascinating art form.

Our personalized support service is there to answer all your questions. Whether you’re a beginner or an expert collector, we’re here to help.